In the 1820s Joseph Thomas Treffry, a local landowner from Fowey, started expanding his commercial interests by purchasing a copper mine at Lanescot. Later he bought the Fowey Consols mine.

In 1829 he started building a new canal through the Par valley and a new harbour at Par (or Porth, as it was called then) to enable easier transportation of copper ore.

By 1835 the canal was complete and Par Harbour was fully operational, with its own blacksmiths, ship repairers, lime kilns, coal wharves, timber pickling pits, smelting works, and later a flour mill.

Treffry acquired a wide variety of interests including: Par Consols mine above Par Harbour; shipping based in Fowey and Par; granite quarries in the Upper Luxulyan Valley; and clay works further inland at Hensbarrow.

To facilitate further expansion, Treffry set about improving communications inland. His first scheme was the construction of a horse-drawn tramway up the Luxulyan Valley. It was eventually abandoned, possibly because of the ineptitude of the chosen contractors.

In 1838 Cornwall he purchased the (then) tiny fishing village of Newquay on the North Cornwall coast, from which he hoped to export ore and import coal.

In 1839, Treffry started constructing the Carmears Incline. This was a massive inclined plane (powered by a large waterwheel), which rose 300ft from Ponts Mill to the high point on the eastern side of the Luxulyan Valley.

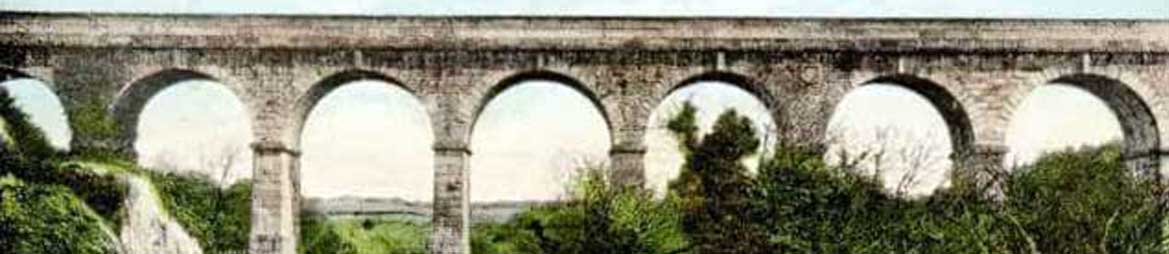

It took until 1841 to complete the Carmears Incline, but meanwhile Treffry had commenced another project – The Treffry Viaduct – which would provide access to the granite quarries of Colcerrow. This fulfilled a dual purpose, carrying the tramway across the Valley to Cam Bridges and Luxulyan, and water from the hills above down to the Carmears Waterwheel and the Fowey Consols Leat.

By 1845 this extraordinary industrial complex was fully operational. Inwards traffic from Par included lime for agriculture and coal for the mines and clay works of Hensbarrow; outwards traffic was china clay, granite from Luxulyan valley, and lead ores from the mines at Newlyn Downs for the smelter at Par.

However in the 1840s copper production from Fowey Consols Mine halved, partly due to the exhaustion of many of the richest seams of ore, but also to the drop in the price of the copper itself.

In 1844 over 12,000 tons of copper ore was produced and sold for over £65,000, but….

By 1847 only 6,000 tons were being produced and the income was only just over £32,000.

The continuation of the tramway to Newquay was well under way but Treffry’s health was failing and when he died, aged 68 in 1850, the line was not complete.

Treffry’s successor completed the Newquay line and built a new horse-drawn tramway from Ponts Mill to Par, which replaced the canal in function.

In the 1850s, however, copper prices dropped further and no further expansion took place. Tin mining was tried for a while, but for the remaining part of the 19th century granite became the premier export.

By 1870 the Treffry tramway system through the valley was one of only two remaining in Cornwall, and was definitely considered to be out-of-date.

In 1872 a consortium of local businessmen, led by a speculator called Roebuck, purchased the entire tramway and set about converting it into a modern railway system. The Cornwall Mineral Railway (CRM) followed the basic route from Par to Newquay, with lengthy branches into the china clay district and an extension from Par to Fowey. William West, who had built a foundry in St Blazey in 1848 (together with an associated gasworks, with a connecting tramway), provided the ironwork for many of the bridges and other works, and with his old colleague William Pease planned a new route through the Luxulyan Valley, rendering the Carmears Incline and Treffry Viaduct obsolete.

The centrepiece of the new system was the head-quarters in St Blazey, where Sir Morton Petoe built the St. Blazey Locomotive Depot in 1874.

The impact of this Cornwall Mineral Railway (CRM), which revolutionised transport within the area, was not necessarily beneficial to the local inhabitants. Horses were largely made redundant and with their demise went a whole range of skills and facilities which were no longer needed. There was less local work available so depopulation followed.

In Ponts Mill, for instance, a population of 80 in 1841 had fallen to just 11 by 1881.

Par Harbour continued to be an important port and a major employer, with its many different businesses – smithies, ship repairers, a mill, timber yards, smelting works, and coal yards. However the decline of mining after the 1870s resulted in a change from tin and copper ore to china clay as its main export.

In 1875 a mill to grind china-stone was built close to Ponts Mill, which used china stone brought down from Hensbarrow. This was powered using the waste water from the Fowey Consols leats. A coal-fired pan-kiln was also built in Ponts Mill to process china clay piped down from Hensbarrow. These facilities expanded during the early 20th century and eventually the complex became the largest group of stone mills in the country.

After 1900 the Luxulyan granite quarries were acquired by the Penryn company of John Freeman, but demand dropped after this time.

They were purchased by ECLP (now Imerys) and used until the 1960s, when the kilns and stone mills were closed down. The main Ponts Mill kiln was then converted to a modern oil-fired drier.

Par Harbour was largely rebuilt by ECCI in the 1960s, although Treffry’s stone harbour arm, stone quays, and sluicing pond remain, nestled amongst the plethora of modern buildings.

In 1999, Ponts Mill oil-fired kiln was the only industry still active in the Luxulyan Valley.