Brannam’s Bottle Kiln is the lonesome survivor of succession of pottery kilns – 5 at one time!

There was a pottery on this site from at least the 17th Century, although it changed in character as it changed in ownership.

The Loverings worked an existing pair of potteries on Litchdon Street, by the River Taw in Barnstaple, and sold them to the Rendell family in 1830. It became known as the Litchdon Street Pottery and by 1840 Thomas Brannam had leased it. Thomas Brannam was making utility-type wares, such as drains, bricks and roofing tiles, but also country pottery. The pottery was rebuilt between 1843 and 1886 during which time Thomas was joined by his artistic son Charles.

Initially educated in the theory and practice of ceramics, young Charles was encouraged by a local dignitary, William Frederick Rock, who invited him to London where he studied pottery in the various museums.

In 1886 the Litchdon works were run by Thomas’ son, Charles Brannam, and it was rebuilt again! And later in 1889 the workshops were extended further and in 1903 the frontage was decorated in yellow and red brick. This elaborate frontage was common and was an early example of industrial tourism.

The pottery gained Royal patronage from Queen Victoria in 1885, which spurred demand for the art pottery. So in 1886 Charles registered the name Royal Barum Ware and ensured it was sold by several London firms including Liberty.

By 1904 the works expanded yet again into the open land between it and Trinity Street and in 1913 Charles handed the business over to his 2 sons – Charles and Jack.

The Litchdon Street Pottery remained in the Brannam family until 1979!

The earliest kiln was originally constructed outside, but by 1886 it had become enclosed within the workshops – it continued in use until its demolition around 1910!

Excavation revealed the octagonal rubble and brick foundations of the updraught kiln. The 2nd kiln was built circa 1900 to the north-east of the first, originally as an updraught kiln but later converted to a ‘Minton’ downdraught.

A further 3 kilns were built on the site with 2 still in occasional use until 1971, although they had been converted to oil firing in 1963.

Of the five kilns, only one remains – and it’s grade II listed!

There were many potteries in North Devon because of the fabulous quality of the Fremington Clay Bed, such as the Combrew Clay. All the potteries across the region (including Bideford) extracted the clay from pits in the Fremington region and clay was a major industry here. Leases on potteries, kilns, clay pits and clay ports were commonplace and often ran in families. The other notable family of potters were the Fishleys of Fremington.

The Fremington Clay is well known as the only likely glacial deposit on the South West England mainland. It is dark reddish brown in colour, very different to the nearby Ball clays, which were bright white!

Clay, even within the Fremington Clay Series (Bed), varied slightly from pit to pit, so finding the right clay and protecting it became quite an ordeal!

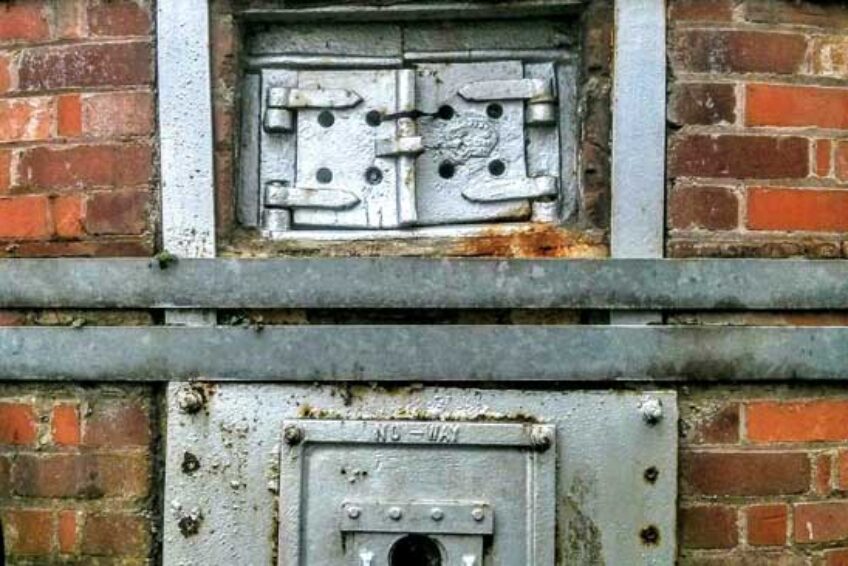

The bottle kilns elsewhere have an inner kiln and an outer bottle-shaped structure, acting as a temperature regulator, made of bricks; like those at Coalport up in Ironbridge. Hwever, this interesting structure appears to have been slightly different. Maybe it has been relocated at some point, or maybe, as was suggested somewhere, it was originally inside a building, presumably with just the top bottle-neck structure emerging.

Brannam’s Bottle Kiln was built to be coal-fired, but was converted to gas in the 1960s. You can view the preserved kiln today because it remains in situ, although a doctors surgery has sprung up around it now. It makes a most brilliant feature to the garden. You can also see the top of the kiln peeping between the roofs, across the car park, if you know where to look!

The Barnstaple Museum (Free admission) has a fabulous collection of pottery from Brannams and across the region.

Brannam’s Bottle Kiln is the lonesome survivor of succession of pottery kilns – 5 at one time!

There was a pottery on this site from at least the 17th Century, although it changed in character as it changed in ownership.

The Loverings worked an existing pair of potteries on Litchdon Street, by the River Taw in Barnstaple, and sold them to the Rendell family in 1830. It became known as the Litchdon Street Pottery and by 1840 Thomas Brannam had leased it. Thomas Brannam was making utility-type wares, such as drains, bricks and roofing tiles, but also country pottery. The pottery was rebuilt between 1843 and 1886 during which time Thomas was joined by his artistic son Charles.

Initially educated in the theory and practice of ceramics, young Charles was encouraged by a local dignitary, William Frederick Rock, who invited him to London where he studied pottery in the various museums.

In 1886 the Litchdon works were run by Thomas’ son, Charles Brannam, and it was rebuilt again! And later in 1889 the workshops were extended further and in 1903 the frontage was decorated in yellow and red brick. This elaborate frontage was common and was an early example of industrial tourism.

The pottery gained Royal patronage from Queen Victoria in 1885, which spurred demand for the art pottery. So in 1886 Charles registered the name Royal Barum Ware and ensured it was sold by several London firms including Liberty.

By 1904 the works expanded yet again into the open land between it and Trinity Street and in 1913 Charles handed the business over to his 2 sons – Charles and Jack.

The Litchdon Street Pottery remained in the Brannam family until 1979!

The earliest kiln was originally constructed outside, but by 1886 it had become enclosed within the workshops – it continued in use until its demolition around 1910!

Excavation revealed the octagonal rubble and brick foundations of the updraught kiln. The 2nd kiln was built circa 1900 to the north-east of the first, originally as an updraught kiln but later converted to a ‘Minton’ downdraught.

A further 3 kilns were built on the site with 2 still in occasional use until 1971, although they had been converted to oil firing in 1963.

Of the five kilns, only one remains – and it’s grade II listed!

There were many potteries in North Devon because of the fabulous quality of the Fremington Clay Bed, such as the Combrew Clay. All the potteries across the region (including Bideford) extracted the clay from pits in the Fremington region and clay was a major industry here. Leases on potteries, kilns, clay pits and clay ports were commonplace and often ran in families. The other notable family of potters were the Fishleys of Fremington.

The Fremington Clay is well known as the only likely glacial deposit on the South West England mainland. It is dark reddish brown in colour, very different to the nearby Ball clays, which were bright white!

Clay, even within the Fremington Clay Series (Bed), varied slightly from pit to pit, so finding the right clay and protecting it became quite an ordeal!

The bottle kilns elsewhere have an inner kiln and an outer bottle-shaped structure, acting as a temperature regulator, made of bricks; like those at Coalport up in Ironbridge. Hwever, this interesting structure appears to have been slightly different. Maybe it has been relocated at some point, or maybe, as was suggested somewhere, it was originally inside a building, presumably with just the top bottle-neck structure emerging.

Brannam’s Bottle Kiln was built to be coal-fired, but was converted to gas in the 1960s. You can view the preserved kiln today because it remains in situ, although a doctors surgery has sprung up around it now. It makes a most brilliant feature to the garden. You can also see the top of the kiln peeping between the roofs, across the car park, if you know where to look!

The Barnstaple Museum (Free admission) has a fabulous collection of pottery from Brannams and across the region.